Biological ZBB sewage treatment plants

ZBB sewage treatment plants, often used as home sewage treatment plants, are offered in the compact version. They workon the basis of the sewage treatment backed up with the method of active deposit with fluidized bed (hybrid arrangement). Applying the fluidized bed enables the work of the sewage treatment plant to achieve the high stability towards the typical solutions based on theactive deposit.

Biological sewage treatment plants are offered by the producer Wobet-Hydret in the base version (ZBB-C) or vertical one (ZBB-PC). The body is made from the polythene of the high density and has a bunded structure (HDPE Z). It enables the installation even in soil-grown-water unfavorable conditions and in situations when a big immersion of the drain hampers or prevents the installation of standard structure sewage treatment (e.g. single-walled).

Presented biological sewage treatment plants are integrated with the preliminary settling tank, to which the sewage sludge is recirculated.

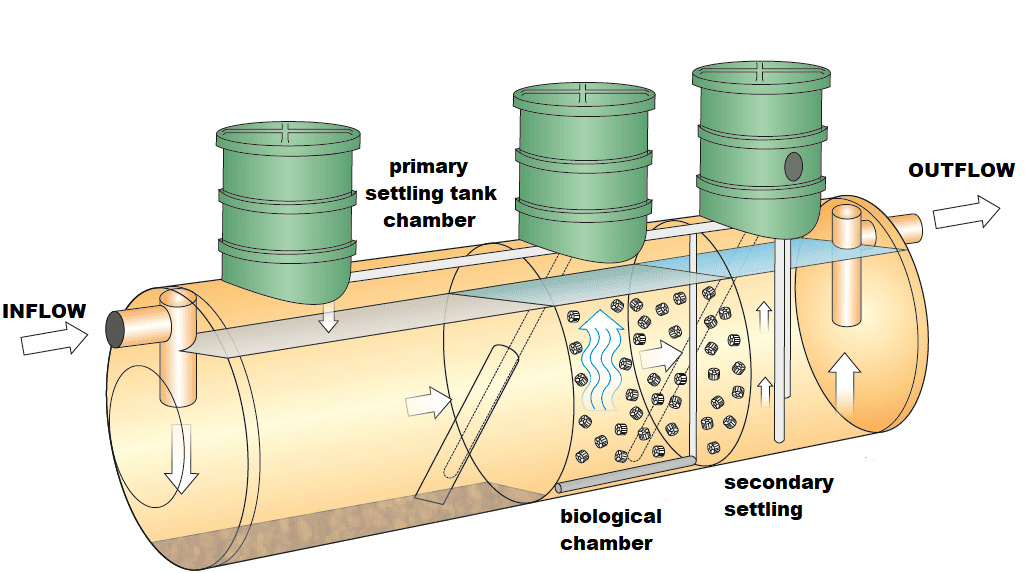

Biological ZBB-C reactor (7-16 RLM)

Biological reactor of the type ZBB-C, is intended the sewage treatment social and welfare. The structure of the reactor is based on the bunded tanks, made from the polythene of the high density.

In the standard version, the reactor is divided into three chambers:

- the chamber of the preliminary settling tank,

- the biological chamber (of oxygenating),

- the chamber of the secondary settling tank (with the recirculation).

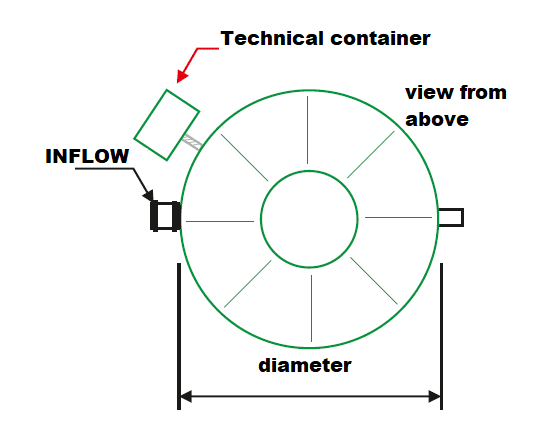

The work control is held in the automatic way. The driver is put in the technical container. The power supply is connected to the box controlling the work of the arrangement of oxygenating and the recirculation of sludge.

The control enables to choose the mode in order to adapt parameters for. In case of the lack of powering online, functions and of placing are supported. After new attaching the power supply a continuation of the work of the sewage treatment plant will take place under the previously chosen procedure. The automatic guidance in the described configuration is also reducing the power consumption as well as is extending the period between next with emptying deposit.

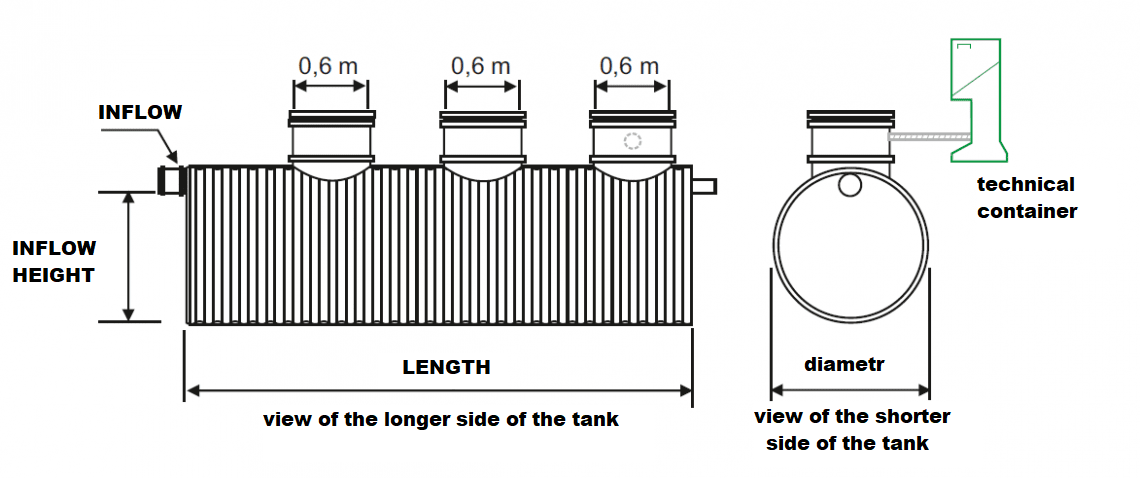

Biological ZBB-C reactor (20-50 RLM)

Biological reactor of the type ZBB-C, is intended the sewage treatment social and welfare. The structure of the reactor is based on the bunded tanks made from the polythene of the high density.

The reactor is divided in the standard version into three chambers:

- the chamber of the preliminary settling (where the retention of the cargo of flowing sewage takes place),

- biological chamber (oxygenate),

-

the chamber of the secondary settlement tank.

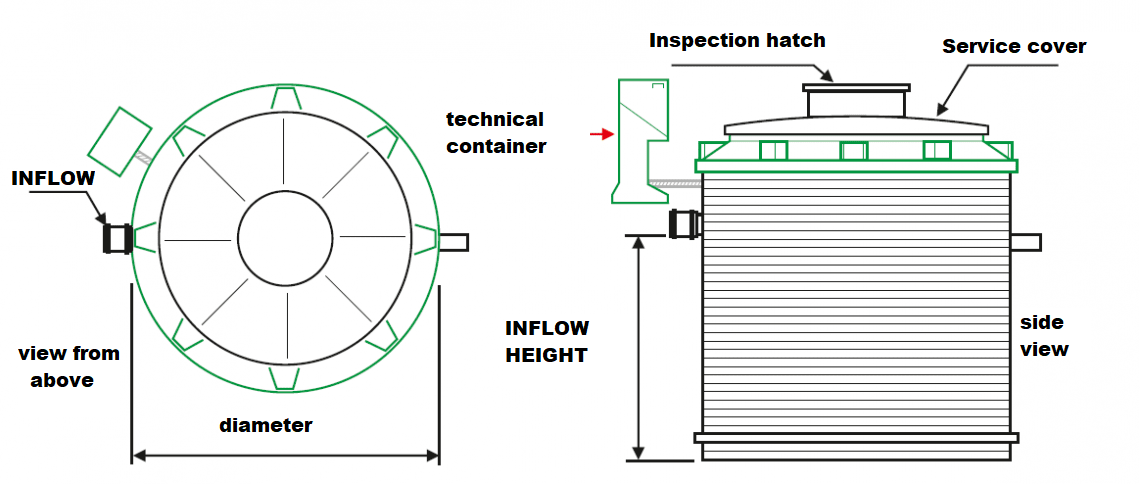

Biological ZBB-PC reactor (6-10 RLM)

The biological reactor of the ZBB-PC type, is intended to clean the domestic waste water . The structure of the reactor is based on the bunded tanks, made from the polythene of the high density.

The reactor is divided in the standard version in three chambers:

- the chamber of the preliminary settling tank ,

- the biological chamber (of oxygenating),

- the chamber of the secondary settlement tank (with the recirculation).

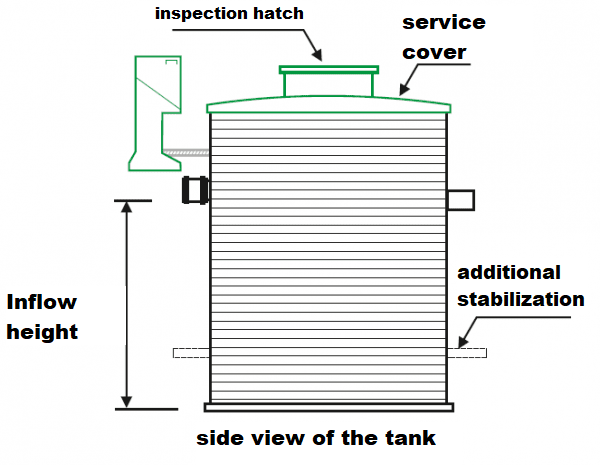

The control of the work is held automatically, through the technical container installed by the sewage treatment plant. The 1-phase power supply is being connected to the box controlling the work of the arrangement of oxygenating and the recirculation of deposit. Additional controlling enables to choose the work mode or the holiday mode in order to adapt parameters for her to needs of the customer. In case of the lack of powering online functions and of placing are supported in the driver.

It is recommended, while placing an order, to to establish the exact plunging the inflow to the reactor of the sewage treatment plant in order to extend, or to shorten the superstructure of the manhole (of the body).

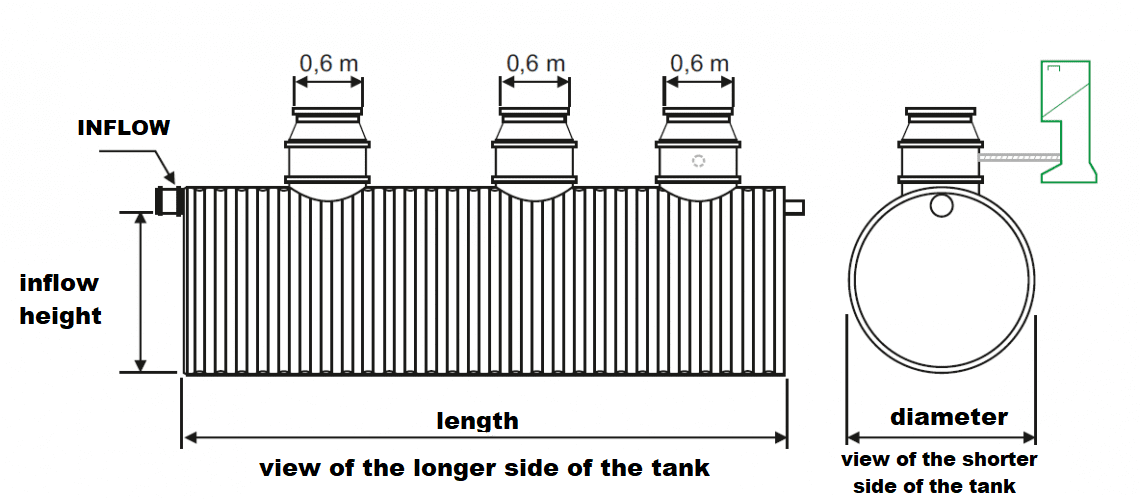

Biological ZBB-PC reactor (15-32 RLM)

Biological reactor of the type ZBB-PC, is intended clean the domestic waste water . The structure of the reactor is based on the bunded tanks, made from the polythene of the high density.

The reactor is divided in the standard version in three chambers:

- the chamber of the preliminary settling tank,

- the biological chamber (of oxygenating),

- the chamber of the secondary settlement tank (with the recirculation).

The control of the work is held automatically, through the technical container installed by the sewage treatment plant. The 1-phase power supply is being connected to the box controlling the work of the arrangement of oxygenating and the recirculation of deposit. Additional controlling enables to choose the work mode or the holiday mode in order to adapt parameters for her to needs of the customer. In case of the lack of powering online functions and of placing are supported in the driver.

It is recommended, while placing an order, to to establish the exact plunging the inflow to the reactor of the sewage treatment plant in order to extend, or to shorten the superstructure of the manhole (of the body).